Last year, when I installed the how water heater, I never had time to plumb the internal heat exchanger. So, the hot water heater worked fine, but in order to actually get hot water, I had to be plugged in to shore power, or run the generator for power, and then wait for the heating elements to warm the water.

The HWH also has an engine coolant driven heat exchanger inside the unit, so hot water can be created from excess engine heat. That way, when we pull into port, the water is already hot - no need to wait.

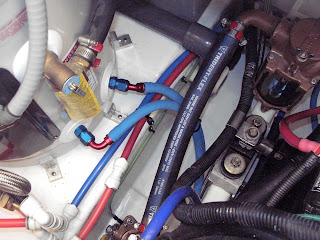

So, to hook it up, 2 hoses have to be connected from the engine coolant system to the hot water heater - a supply line, and a return line for engine coolant. I don't like everyday heater hoses, along with conventional nipples and hose clamps, so I decided to use something a little more elegant. I had some left over hose from the oil change system, Aeroquip's "socketless" hose, so I ordered more hose ends, and used that.

For safety and redundancy, I also milled out a couple custom aluminum brackets to mount ball valves in the lines, so if the HWH heat exchanger fails, I can isolate the engine from it. They look like this:

The valves are brass, full port ball valves. You can also see some of the socketless fittings in the pic.

I ran the hoses along the stringers, tucked out of the way, so they won't get stepped on during maintenance procedures. The valves face up, so they can be accessed and shut off rapidly, if need be.

And there it is. The hoses are secured to the stringers every 8 inches or so, and have chafe protection at strategic points, so I don't have any surprises down the road.

Once I was done, I cleaned the entire bilge, and she's now ready for the summer:

Won't be long now!!!

This comment has been removed by a blog administrator.

ReplyDeleteI prefer this send. It’s fantastic to uncover anyone verbalize through your heart and as well excellent on this critical intended theme can be easily viewed. faulty wiring

ReplyDelete